After terminating my contractor, many alarming problems surfaced in the house, among them a seemingly harmless chimney.

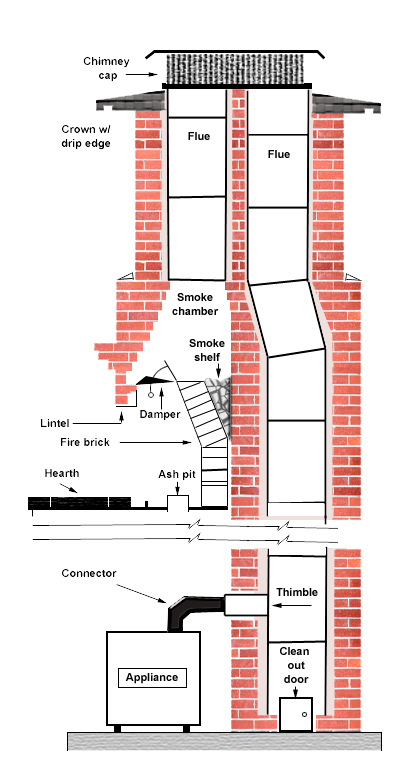

Some people think a flue is the same as a vent, or they think that flues are chimneys. But neither is correct. A chimney is a structure that connects your fireplace to the outside, but what is a flue?

A flue is a passage through which air, gas, or smoke is moved outdoors. It is usually functions as part of a heating system, such as a fireplace, boiler, or furnace though any fire appliance will need venting. An unlined chimney is technically a flue because it is designed to carry combustion gases and smoke from any kind of firebox (fireplace, wood-burning stove, etc.) to the outside of a building.

Flues are necessary because, without them, toxic fumes and gases would be released inside the home. A chimney flue needs to be well-constructed to maximize its venting efficiency and minimize the danger of unwanted fires. If smoke and heat escape the chimney and come into contact with combustible materials within the home, such as wood framing, foam, or drywall, it can cause a fire.

Chimneys are generally the preferred option for venting, but if you can’t use your chimney or if it’s already at venting capacity, then appliances can be vented using specialized flues.

Flues vs. other kinds of vents

What distinguishes a flue from an HVAC or kitchen vent, for example, is that flues are made of materials that can withstand heat. While both kitchen vents and flues involve directing air or gases outside, a kitchen vent removes cooking byproducts, whereas a flue is specifically for removing combustion gases. A chimney may have one flue or more. Separate flues might be necessary to ensure safe and efficient venting for different appliances, especially if they use different fuels, have distinct venting requirements or the building codes and regulations dictate separate vents. For example, if you have a wood stove and a fireplace, they usually cannot be vented into the same chimney.

House age and types of flues

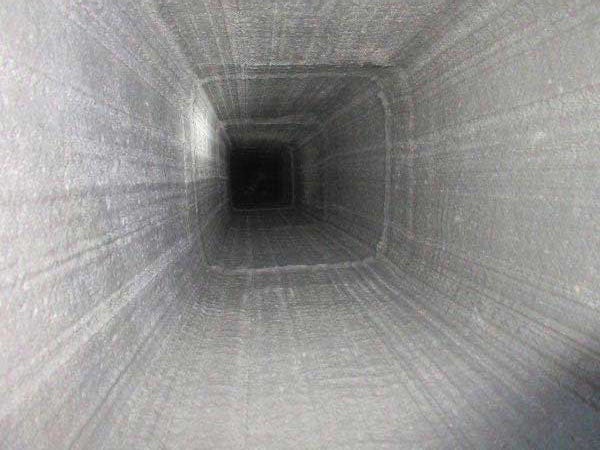

The age of a house will usually determine the type of flue it has, with older houses typically having more traditional flues. You can identify the flue by looking down the chimney from the roof or up the fireplace.

Older houses will have masonry parged flues

Masonry parged flues are typical in houses that were built prior to 1960, where the chimneys were made of brick or stone and lined with lime mortar.

Drawbacks:

These flues are not well-insulated and can result in issues with air uptake in the chimney.

Lime mortar can absorb combustible substances like soot and creosote (a byproduct of burning wood). Creosote will eventually dissolve the binder in the mortar joints.

It's crucial to schedule regular cleaning and inspection of all flues, but particularly masonry ones. Many chimney companies offer camera inspections, where a camera is inserted into the flue to assess its condition.

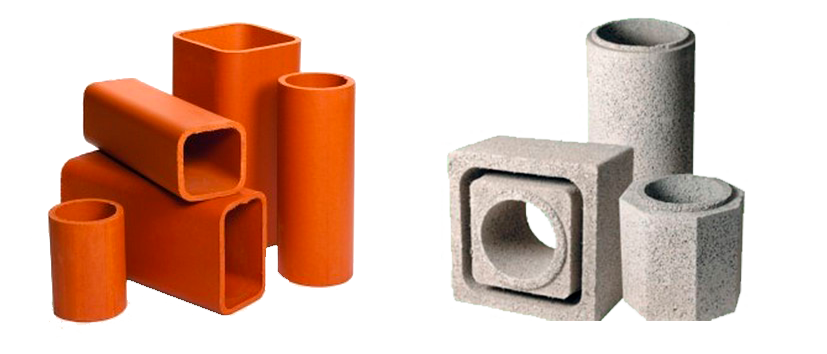

Later houses will have concrete, pumice, or clay-lined flues

Houses constructed post-1960 were commonly lined with clay, pumice, etc. due to their insulation properties, ability to withstand high temperature fluctuations, and ability to provide good air flow compared to lime mortar.

These flues are available in multiple shapes and sizes, including round, square, and rectangular variations for different chimney configurations. Thicker liners offer superior insulation and durability. Both clay and pumice liners are widely available today.

Drawbacks:

They are susceptible to cracking during chimney fires, as the rapid expansion and contraction caused by heat can damage the material.

Tiles may deteriorate over time if exposed to condensation in a gas flue, especially if improperly sized or large temperature differentials occur.

Relining can pose challenges due to limited access. Also while the tiles are cheap, it is a labor-intensive installation.

Modern liners

Nowadays, older chimneys are often repaired with cast-in-place concrete, stainless steel liners or newer coatings.

Stainless steel flue liners

Stainless steel flue liners are a popular choice due to their ease of installation. These consist of a flexible, corrugated metal tube available in several grades. Common grades include 304L for wood burning, 316L, which is the most common and suitable for seasoned wood or gas fires, and 904L, which is recommended for high-temperature fuels like coal and comes with a longer warranty. Prior to installation, the dimensions of the chimney are measured accurately to ensure the correct size and length. Installation involves pushing the steel liner through the chimney from the roof.

Steel flues can be installed internally or externally. The lifespan is about 15–25 years. These also come in aluminum which is less durable. Keep in mind that metal chimney flues do require cleaning, just like other materials.

Drawbacks:

Usually the most expensive option

They need to be correctly sized so that they don’t significantly reduce the inside dimension of the flue. If the liner is too small, it may impede proper draft and ventilation.

The transition from the smaller, round flue to the larger throat above the fireplace can cause issues, as the chimney may turn at this point. This may necessitate opening up walls near the fireplace, which will then need to be repaired.

Steel is not as insulating as other options. For chimneys located on exterior walls, insulation should be used to reduce creosote buildup, improve draft efficiency and reduce condensation which can corrode the steel and reduce its lifespan.

Cast-in-place concrete (Golden Flue etc.)

Cast-in-place chimney liners involve the use of a concrete mix that is poured around a heavy rubber tube that is inserted down the full length of the chimney. The concrete cures overnight, and the tube is removed the next day. This method allows the cement to seep into cracks and holes in the existing chimney, providing structural stability and creating an insulated flue. Concrete coatings can last over 50 years.

Drawbacks:

They can be challenging to install due to the precise placement of the form and the pumping of the concrete mix.

If the chimney is structurally compromised, this method is not advisable as it may cause interior collapse.

Ceramic and refractory coatings (Thermocrete, Heat Shield, FireGuard etc.)

Ceramic coatings involves the application of a sprayable ceramic material that effectively seals holes and cracks while simultaneously strengthening the chimney. The install is fairly fast and a benefit is that it does not reduce the venting area of the chimney by much. It is also very durable and will last 25–50 years. It’s also a good option when the chimney has a lot of turns and it is difficult to install a steel liner.

A pumice based coating (Isokoat) is another option which is applied by hand. It will seal the flue and also stabilize the internal structure of the flue.

Drawbacks:

These coatings may not be suitable for all types of chimneys or flues. For example, some coatings are too thin to be considered a stand alone liner for solid fuels (wood, coal, charcoal etc) which means you’d have to line the chimney some other way first.

It may not be effective in cases where the existing chimney is severely damaged or structurally unsound.

Ceramic coatings can be difficult to install.

Thin coatings will not provide insulations so the chimney must be cleaned more often to reduce condensation.

Resin liners (Furanflex, Proform, etc.)

Resin chimney liners work by creating a seamless and durable coating. A flexible liner made of resin is inserted into the flue. Once in place, the liner is inflated and pressurized, either with air or steam, causing the resin to harden and form a solid composite structure. Resin liners have a lifespan of about 25 years.

Drawbacks:

Resin lining systems can be more expensive than traditional methods like clay tile liners.

If not properly installed, resin liners may develop wrinkles, folds, or other imperfections that can compromise their effectiveness.

Other considerations

Suitability (important!)

Some liners may not be suitable for all chimney configurations or applications. Factors such as the existing material of the chimney, the appliance, the fuel its height, and other structural considerations can influence the suitability of a particular liner for a given chimney.

Tip: Don’t ask the installer about suitability as you may get varying answers. Call the manufacturer and read the specifications.

Sizing

With any liner, there should be adequate room for smoke passage and draft movement. This means flues must be carefully sized in relation to appliance capacity, chimney height etc.

Shape & surface

Smoke swirls upward, so round flues are more efficient than square flues because they don’t obstruct the natural flow of gas. For good performance, flues should have a smooth inner surface without obstructions.

Maintenance

Make sure to inspect the chimney flue annually, which will indicate if cleaning is needed. Pay attention if the creosote buildup exceeds 1/4 inch on the flue walls, you see water leaks or white residue inside the chimney. Additionally, if you spot soot or oily creosote falling into the firebox while a fire is burning, it's time for a cleaning. A chimney cap can prevent debris, animals, and rainwater from entering the flue and blocking air flow.

Our flue was a top prospect for potential homicide.

We have gas boilers that provide hot water to our forced-air heating system (see Repository at the end). Gas boilers need to be vented for smooth water flow, as otherwise air will get trapped and can disrupt circulation. Additionally, vents create a safe passage for combustion air to be released outside.

In our case, instead of the air ascending the chimney, it was being forced back into the boiler room and was releasing harmful gases into the house.

Tip: How to check for backdraft (air that’s not flowing up the flue)

Smoke test: light incense or a candle near the flue connection while the boiler or appliance is operating. If smoke is drawn into the flue, it indicates proper venting. But if the smoke reverses direction and enters the room, it indicates a backdraft.

Carbon monoxide (CO) detector: Install a carbon monoxide detector near the boiler or appliance and throughout the living space. Elevated levels of carbon monoxide can indicate potential issues.

How we fixed our flue

A backdraft doesn’t necessarily mean the flue is the problem, but it is one indication. Aside from the backdraft, masonry chimneys do deteriorate over time due to exposure to heat, moisture, and combustion. So we thought it would be safest to line the chimney. We opted for a stainless steel liner for which were quoted between $6,000 to $11,000.

On the day of installation, the company arrived with the tube which they carried up to the roof. The installation process, spanning multiple floors, took several hours. The installer had cautioned us about the possibility of the tube getting stuck near fireplaces, which would have require opening the walls.

They mentioned that they would only patch walls but wouldn't be responsible for finishing them—something to clarify beforehand. However, we were lucky as we didn’t end up having to other than the fireplace in the cellar. Additionally, they also did all the necessary venting calculations to make sure that the flue could handle the capacity. For the DIYers, you can buy a tube online. Amazon has one for $600 and they are also available at Home Depot.

PS You don’t need to immediately go line your chimney if you have a backdraft. Have it video inspected and cleaned first then make sure you need the liner because the masonry has deteriorated. We just felt it was safer. 1) It is easier to replace a liner than repair brick. 2) Masonry chimneys were designed for burning wood not acidic flue gases from a boiler which can damage the masonry so it is safer to have a liner.

Keep in mind:

Reducing the flue size to the point where it is too small can cause smoke, carbon monoxide and other substances to enter the home.

Your appliance manual will have details like the BTU rating, fuel type, combustion efficiency, and flue gas temperature to help you size and find the right type of flue.

Additionally, local building codes and NFPA (National Fire Protection Association) often dictate specific requirements for venting. For instance, in places like New York City, venting regulations can be stringent, dictating precise methods and locations for vent placement. For example, regulations may prohibit boilers from being vented too close to windows or property lines.

While chimneys are commonly used for venting, there are situations where they may not be viable options.

If you liked this post, I would appreciate it if you heart or share it. Thank you.

Related content:

Why My House Is Still Freezing

(Paid subscriber post) Years of suffering in a cold house required me to piece together the root of the problem. Here's everything you need to know at a high level. In later posts, I'll go into greater detail on some of these issues. If you like the post, please support me by sharing it or liking it.

R-Value: A Measure of Insulation Effectiveness

(Paid post) R-values measure the effectiveness of insulation. The topic is covered extensively but I wanted to distill the information in a way that could be easily understood.

Queen’s Repository

Boiler

An appliance that heats water to warm your home and sometimes to provide hot water for showering, bathing, washing dishes. It can be powered by different sources like natural gas, oil, or electricity.

Creosote

Creosote is a dark brown or black oily liquid that is produced when organic materials such as wood, coal, or oil are burned incompletely. It consists mainly of tar, phenols, and other organic compounds. It is a known carcinogen and can be harmful to human health if ingested or inhaled in large quantities.

NFPA

The National Fire Protection Association (NFPA) is an organization dedicated to fire prevention and safety standards. NFPA-211 standards provide guidelines to prevent hazards associated with improper chimney dimensions. NFPA-211 specifies that interior chimneys, which are contained within the heated portion of a building until they exit the roof, must adhere to specific flue size limitations. These limitations dictate that the flue opening size should not exceed three times the size of the exhaust opening on the stove.

For chimneys that run up the exterior of a building, NFPA-211 stipulates that the flue opening size should not be more than twice the size of the stove's exhaust opening. This requirement ensures that the chimney adequately accommodates the stove's emissions while minimizing the risk of smoke and gases backing up into the building.

Yay! I’m so happy to hear your nightmare suit has ended!! 🌈🔆💪

Clarity is the hallmark of R Q''s writing. This piece i particular is of vital importance as errors/ defects can have a hazardous impact on our health.